Drug-Layering Core Pellets with Wurster Fluidized Bed Technology

Drug-Layering Core Pellets Overview

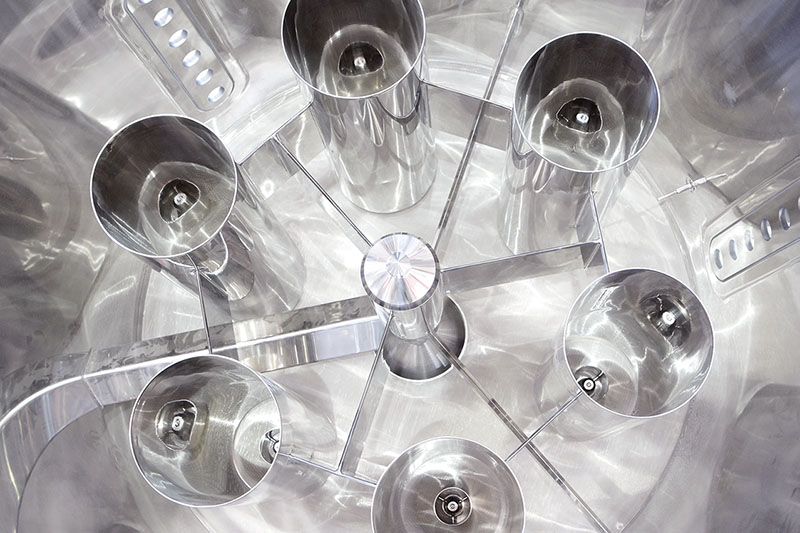

Drug-layering core pellets use Wurster fluidized bed technology, also called bottom-spray coating, which remains the most preferred method in pharmaceutical manufacturing. Usually, sugar or microcrystalline cellulose (MCC) starter pellets serve as the base. In this batch process, a liquid containing the active pharmaceutical ingredient (API) coats pellets which as in size 100 μm or larger. However, the API must remain chemically stable in the layering solution.

Advantages of Wurster Technology for Drug-Layering Core Pellets

Efficient for Low- to Medium-Dose APIs

Wurster technology works very well for low drug loads. Therefore, it ensures excellent content uniformity. For low- to medium-dose APIs, the minimum core particle size should be about 200 μm.

Flexible Drug Load Capacity

The API content in drug-layered core pellets ranges from less than 0.1% to 80%. Typically, a single layering step achieves up to 60% drug load. When splitting the batch into multiple steps higher values are accessible.

Consistent Quality and Uniformity

Both bulk uniformity and content uniformity are critical for low-dose drugs. Moreover, Wurster technology ensures even drug distribution, producing highly homogeneous pellets.

Drug Layering Applications

Summary

Drug-layering core pellets using Wurster technology offer precise, scalable, and uniform drug coating. Furthermore, this method works for low- and high-dose APIs. Therefore, manufacturers achieve consistent quality, high yield, and excellent content uniformity, making Wurster fluidized bed technology the preferred choice for drug-layered pellets.

References

[1] Multiparticulates, Modern Oral Drug Products for our Society – Part 1,1; seminar series by Dr. Norbert Pöllinger.

Expert’s opinion

The Wurster (bottom spray) fluidized bed technology is the most commonly used and preferred method for drug-layering core pellets. Most likely starter beads are sugar or MCC starter pellets. In this batch process, a liquid containing the active pharmaceutical ingredient (API) is applied to starter pellets that are 100 μm or larger.

ingredientpharm

ingredientpharm